Soo saaraha Alxanka Gawaarida ugu Fiican iyo Warshada Shiinaha

Horumarinta Shirkadda

- 2011, TTM waxaa lagu aasaasay ShenZhen.

- 2012, U guurista DongGuan;Dhisida xiriirka iskaashiga ee Magna International Inc.

- In 2013 Soo bandhigida qalab aad u horumarsan.

- 2016, waxay soo bandhigtay qalab CMM oo ballaaran iyo qalabka 5 dhidibka CNC;La kaashaday OEM Ford Completed Porsche, Lamborghini iyo Tesla CF mashaariicda.

- 2017, U guurista goobta dhirta hadda jirta;CNC ayaa laga kordhiyey 8 ilaa 17 qaybood.Top Talent Automotive Fixtures & Jigs Co.Ltd ayaa la aasaasay

- 2018, La kaashaday LEVDEO automotive oo waxay dhamaystirtay khadka wax soo saarka otomaatiga.4-xawaaraha sare ee CNC ayaa la soo bandhigay, wadarta Qty ee CNC waxay gaartay 21.

- 2019, Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd ayaa la aasaasay.(Hal joogsi joogsi ah) Waxay la kaashadeen Tesla Shanghai iyo Sodecia Germany.Waxa loo dhisay shaybaadhka R&D cusub ee otomaatiga ah.

- 2020, la kaashaday OEM ISUZU ee SA; Waxay dhamaystirtay Adeegga Hal-Stop ee RG06.

- 2021, horay loogu sii socdo aaminaadda tayada si loo abuuro ganacsi heer caalami ah.

- 2022, xafiiska kooxda TTM waxaa laga aasaasay Dongguan City, New CNC 4 axis * 5 sets, New Press * 630 tan, Hexagon Absolute Arm.

- 2023, TTM waxay dhisaysaa warshad cusub oo loogu talagalay hubinta qalabka iyo ganacsiga qalabka alxanka;ku darida hal 2000T saxaafad.

Hubinta Qalabka & Welding Jigs Warshada (Guud ahaan bedka: 9000m²)

Qalabka Shaabadaynta & Dhimashada iyo Wershada Qaybaha Mashiinnada (Guud ahaan bedka: 16000m²)

Sharaxaada Alaabta

| Magaca Alaabta | Qalabka alxanka |

| Codsiga | Automotive CCB, Front End, WS Spring Link, Front Bamper iwm. |

| Nooca alxanka | Alxanka Spot, Alxanka Arc, (CNC/Assembly) Qalabka alxanka gaarka ah |

| Astaanta Qaybta Pneumatic | SMC, FESTO, TUENKERS, CKD, Gacan-qabsiga |

| Calaamadda Qaybta Korantada | OMRON, Mitsubishi, Siemens, Balluff |

| Qalab | 45# Birta, Copper, Stainless Steel |

| Habka Hawlgalka | alxanka Robot, alxanka gacanta, alxanka mishiinka gaarka ah |

| Habka Xakamaynta | Xakamaynta Hawada (Valve Control Pneumatic) |

| Jidka isku dhufashada | Pneumatic, Buugga |

| Jidka Isgaadhsiinta ee Unugyada alxanka | EtherCAT, PROFINET, CC-LINK |

| Sanduuqa Gudbinta Isgaadhsiinta | Habka santuuqa korontada, Nooca godka degdega ah, nooca jasiiradda Solenoid valve |

| Nooca saldhiga alxanka | Dhulka go'an, Boosiye/Flip Tye |

| Jidka dhuumaha | Tuubbada lakabka ah, tuubada ololka celisa, Tube Copper/Stael tube |

| Daawaynta Dusha Joogta ah | Rinjiyeynta, Rinjiyeynta+Black Oxidization, Zinc-Dahaaran, Rinjiyeynta budada |

| Waqtiga Hogaaminta | 2-4 toddobaad ee naqshadeynta iyo dib u eegista naqshadeynta; 10-12 toddobaad ee wax soo saarka ka dib ansixinta naqshadeynta 7-10 Maalmaha shaqada ee maraakiibta hawada; 4-5 toddobaad ee cabista badda |

| Geeri Nolosha | Waxay ku xiran tahay awoodda wax soo saarka macmiilka |

| Caymiska Tayada | Kormeerka CMM Tijaabi muunado Iibsashada goobta Shirka Shabakadda Fiidiyowga ah ee khadka tooska ah iibso Xallinta Dhibaatooyinka Iibka-Off |

| Xidhmada | Sanduuqyada alwaaxyada ee shaybaarada, sanduuqyada alwaaxyada ama sagxadaha qalabka lagu rakibo; |

Baabuurqalabka alxankawaa qalab muhiim u ah habka wax soo saarka baabuurta.Qalabkan khaaska ah waxaa loogu talagalay in lagu hubiyo toosinta saxda ah iyo isu-ururinta qaybaha kala duwan, fududaynta alxanka chassis, baararka jidhka, iyo qaybaha kale ee muhiimka ah.Dulmarkan dhamaystiran, waxaanu ku baari doonaa dhinacyada muhiimka ah ee qalabka alxanka baabuurta, oo ay ku jiraan muhiimadooda, tixgalinta naqshadaynta, samaynta, ilaalinta tayada, iyo doorka ay ku leeyihiin warshadaha baabuurta.1. Muhiimada Qalabka Alxanka Baabuurta:

Qalabka alxanka ee baabuurta ayaa door muhiim ah ka ciyaara soo saarista baabuurta sababo dhowr ah dartood: Saxnaanta: Waxay xaqiijiyaan isku-habboonaanta saxda ah ee qaybaha, taasoo horseedaysa alxanyo joogto ah oo sax ah.Tani waxay muhiim u tahay hufnaanta qaabdhismeedka iyo badbaadada baabuurka.

Waxtarka: Qalabka alxanka ayaa dedejiya habka isu-ururinta, yaraynta wakhtiga wax soo saarka iyo kharashka shaqada.Xaqiijinta Tayada: Adigoo ku haya qaybo ka mid ah boosaska saxda ah, qalabyadu waxay yareeyaan khatarta khaladaadka iyo cilladaha alaabta ugu dambeysa.Joogteynta: Qalabku wuxuu keenaa natiijooyin joogto ah, iyadoon loo eegin heerka xirfadda hawlwadeenka, taas oo lagama maarmaan u ah helitaanka tayada isku midka ah ee gaadiidka.2. Tixgelinta Naqshadeynta: Nakhshadeynta qalabka alxanka baabuurta waa habsocod adag oo ku lug leh tixgelin taxaddar leh oo dhinacyo kala duwan leh: Qaabka Baabuurka: Naqshadaynta qalabka waa in uu waafaqsan yahay samaynta gaarka ah iyo qaabka gaadhiga la soo saarayo.Tani waxay u baahan tahay faham qoto dheer oo ku saabsan shuruudaha isu-ururinta baabuurka.Meelaynta Qaybta: Qalabku waa inuu si sax ah u dhigaa qaybaha kala duwan ee baabuurta, sida muraayadaha jidhka, qaybaha chassis, iyo qaybaha qaab-dhismeedka.Tani waxay ku lug leedahay dhibcaha goobta saxda ah, hababka isku dhejinta, iyo qaababka taageerada.Dulqaadka iyo Is-waafajinta: Injineerada waa in ay tixgeliyaan dulqaadka adag iyo shuruudaha toosinta si loo hubiyo in qaybaha ay si fiican isula jaan qaadaan.

Xulashada Qalabka: Doorashada agabka qalabku waa muhiim.Waa inay noqotaa mid waara, kulayl u adkaysata, oo adag si ay ugu adkaysato habka alxanka.Ergonomics: Qalabka waa in loo qaabeeyey si sahlan isticmaalka iyo badbaadada hawlwadeenka.Tan waxaa ku jira tixgalinta gelitaanka, muuqaalka, iyo ergonomics inta lagu jiro hawlgallada alxanka.3. Farsamaynta Qalabka:

Samaynta qalabka alxanka baabuurta waxay ku lug leedahay dhowr marxaladood:

Naqshadeynta CAD: Naqshadayaasha waxay abuuraan qaabab CAD oo faahfaahsan oo 3D ah ee qalabka, iyagoo tilmaamaya booska, hanuuninta, iyo dhibcaha isku dhufashada ee qayb kasta.Xulashada Qalabka: Iyada oo ku saleysan qeexida naqshadeynta, qalabka ku habboon, badanaa birta ama aluminium, ayaa loo doortaa dhismaha qalabka.Wax-soo-saarka Qaybaha: Qaybaha gaarka ah, oo ay ku jiraan qaab-dhismeedka taageerada, xajinta, iyo walxaha meelaynta, ayaa si sax ah loo soo saaray iyadoo la adeegsanayo mashiinnada CNC iyo farsamooyin kale oo gaar ah.Alxanka iyo Isku-xidhka: Alxaneyaasha iyo farsamayaqaannada xirfadda leh waxay ururiyaan qaybaha, iyaga oo hubinaya inay si sax ah oo ammaan ah isugu habboon yihiin.Tijaabada: Qalabku waxa uu maraa tijaabo adag si loo hubiyo in uu buuxiyo toosinta iyo dulqaadka looga baahan yahay alxanka saxda ah.Tan waxaa ka mid ah ku rakibida qaybaha baabuurka.Qalabaynta: Qalabka waxa loo habeeyey si loo hubiyo in uu ku sii jiro toosan oo uu sii hayo sharaftiisa qaabdhismeed.4. Xakamaynta tayada: Ilaalinta heerarka tayada sare leh inta lagu guda jiro habka wax-soo-saarka qalabka waa lagama maarmaan: Kormeero: Kormeero joogto ah ayaa la sameeyaa si loo xaqiijiyo saxnaanta, adkeysiga, iyo shaqeynta qaybaha qalabka.

Hubinta Dulqaadashada: Cabbiraad sax ah iyo hubinta dulqaadka ayaa la sameeyaa si loo xaqiijiyo in qalabku uu buuxiyo heerarka loo baahan yahay.

Xaqiijinta Iswaafajinta: Qalabka waa la xaqiijiyay si loo hubiyo inay ilaaliyaan toosinta saxda ah iyo jihaynta kulanka.5. Doorka Wershadaha Gawaarida: Qalabka alxanka ee baabuurta ayaa udub dhexaad u ah habka wax soo saarka baabuurta: Alxanka Chassis: Qalabku waxay xaqiijinayaan toosinta saxda ah ee qaybaha chassis-ka, oo ay ku jiraan qaybaha qaybaha iyo qaybaha joojinta.Alxanka Gudigga Jirka: Waxay hayaan dabaylaha jirka, sida albaabbada, koofiyadaha, iyo daahyada, meelaha saxda ah ee alxanka, waxna ka taraya hufnaanta qaabdhismeedka guud ee baabuurka.Alxanka Tolnimada: Qalabka waxaa loo isticmaalaa alxanka tolida, kala-goysyada, iyo isku xirka si loo abuuro curaarta adag oo la isku halayn karo.

Automation alxanka: Xaalado badan, qalabka alxanka waxaa lagu dhex daray unugyada alxanka ee robotka si wax soo saar otomaatig ah loo soo saaro, taas oo sii wanaajisay hufnaanta iyo joogtaynta.6. Habaynta loogu talagalay Soo-saareyaasha Gawaadhida: Soosaarayaasha alxanka baabuurta ayaa inta badan ku takhasusay abuurista qalab gaar ah oo ku habboon baahiyaha gaarka ah ee soo-saareyaasha baabuurta.Qalabkan waxaa loogu talagalay inay la kulmaan heerarka warshadaha gaarka ah iyo shuruudaha, waxaana lagu habeyn karaa noocyada baabuurta ee kala duwan ee dhexda wax soo saarka.Gabagabadii, qalabka alxanka baabuurta ayaa ah qayb muhiim ah oo ka mid ah habka wax soo saarka baabuurta.

Xalka (Adeegyada Furaha Furaha)

Nidaamka Golaha Cad:

1, Khadka Alxanka Jidhka Baabuurka oo Dhammaystiran

2, Keli TaagUnug alxanka

3,Qalabka alxanka iyo Jigsiyada:

CCB ASSYQalabka alxanka, Qalabka alxanka ee Pan ASSY, Qalabka alxanka ee Wheelhouse ASSY, AB Ring ASSY AB Qalabka alxanka, Kursiga ASSY Qalabka alxanka, Kursiga hore ee xubinta alxanka, Qalabka alxanka ASSY dhamaadka hore, Qalabka Dash ASSY Qalabka alxanka, Cowl ASSY Welding Welding Fixture saaraha, shirkadda naqshadeynta iyo warshadda.

Nidaamka Maareynta ISO ee Qalabka alxanka

Kooxdayada qalabka alxanka

Faa'iidooyinkayaga

1.Khibrad qani ah oo ku saabsan wax soo saarka tooska ah iyo maareynta ganacsiga.

2.One Stop Service ee qalabka shaambaynta, hubinta qalabka, alxanka iyo unugyada si loo gaaro wakhtiga iyo badbaadinta kharashka, ku habboonaanta isgaarsiinta, si loo kordhiyo faa'iidada macaamiisha.

3.Kooxda injineernimada xirfada leh si ay u dhamaystiraan GD & T inta u dhaxaysa hal qayb iyo qaybta isku dhafka.

4.Turnkey Xalka Adeegga Shaabadaynta Qalabka, Hubinta Qalabka, Qalabka alxanka iyo Unugyada hal koox.

5.Awood xoog leh oo leh taageero farsamo oo caalami ah iyo iskaashi iskaashi.

6.Big Capacity: Hubinta Fixture, 1500 sets / year; Qalabka alxanka iyo unugyada, 400-600 sets / year;Qalabka Shaabadaynta, 200-300 sets/sanadkii.

Waxaan leenahay in ka badan 352 shaqaale ah, 80% ka mid ah waa injineero sare oo farsamo.Qaybinta qalabaynta: 130 shaqaale, Qaybta qalabka alxanka: 60 shaqaale, hubinta qaybta qalabka: 162 shaqaale, Waxaan leenahay iibka xirfadlayaasha ah & kooxda maareynta mashruuca, adeega muddada dheer ee mashaariicda dibadda, laga bilaabo RFQ ilaa wax soo saarka, shixnadda, iibka ka dib, kooxdayada waxay ku maareyn kartaa dhammaan dhibaatooyinka macaamiisheena Shiinaha, Ingiriisiga iyo Luuqadda Jarmalka.

Waayo-aragnimada Mashaariicda Waaweyn ee Unugyada alxanka iyo Qalabka alxanka

| Mashruuca Qalabaynta Alxanka Weyn (2019-2021) | |||||

| Shayga | Sharaxaada | Nooca | Magaca Mashruuca | Qty(Guud) | Sannadka |

| 1 | CCB WF | Alxanka Arc | VW MEB31 | 60 | 2019-2021 |

| 2 | CCB WF | Alxanka Arc | VW MEB41 | 10 | 2020 |

| 3 | CCB WF | Alxanka Arc | VW 316 | 4 | 2020 |

| 4 | CCB WF | Alxanka Arc | Ford T6 | 8 | 2021 |

| 5 | CCB WF | Alxanka Arc | ISUZU RG06 | 3 | 2020 |

| 6 | CCB WF | Alxanka Arc | Bcar, BSUV | 6 | 2020 |

| 7 | CCB WF | Alxanka Arc | Bcar,BCAR | 7 | 2020 |

| 8 | Dabaqa Dabaqa WF | Welding Sopt | SK326/0RU_K Karooq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Alxanka Arc | WL/WS | 4 | 2019 |

| 10 | Xubin-goysyada garabka WF | Alxanka Arc | WL/WS | 12 | 2019-2021 |

| 11 | Barafka hore ee WF | Alxanka Arc | VW281 | 14 | 2019 |

| 12 | Tusmada ugu hooseysa ee WF | Alxanka Arc | ISSU RG06 | 18 | 2019 |

| 13 | SL ASY iyo MBR iyo EXT ASY | Barta iyo alxanka Arc | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF iyo Unug Qaldan | Alxanka Arc | ISSU RG06 | 6 | 2020 |

| 15 | Kursiga hore ee Laanqayraha WF | Welding Sopt | Volkswagen AG MEB316 (20001) | 4 | 2020 |

| 16 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 1) | 18 | 2020 |

| 17 | Guriga Wheel WF iyo Grippers | Alxanka Arc | Ford BX755 (19018) | 6 | 2020 |

| 18 | AB Ring WF iyo Grippers | Alxanka Arc | Ford BX755 (19018) | 14 | 2020 |

| 19 | Dash Panel WF iyo Grippers | Welding Sopt | Koonfur Afrika Ford T6 (17028-1) | 10 | 2020 |

| 20 | Cowl WF iyo Grippers | Alxanka Spot | Koonfur Afrika Ford T6 (17028-3) | 6 | 2020 |

| 21 | Dhamaadka hore ee WF iyo Grippers | Barta iyo alxanka Arc | Koonfur Afrika Ford T6 (17025) | 10 | 2020 |

| 22 | Rocker WF iyo Grippers | Alxanka Spot | Koonfur Afrika Ford T6 (19029) | 8 | 2020 |

| 23 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 2) | 63 | 2021 |

| 24 | Gadaasha dambe iyo Chassis WF | Alxanka Arc | Ford P703&J73 | 36 | 2020-2021 |

| Mashruuca Qalabaynta Alxanka Weyn (2022) | |||||

| Shayga | Sharaxaada | Nooca | Magaca Mashruuca | Qty(Guud) | Sannadka |

| 25 | Xoojinta Kanaalka Dhexe WF | Welding Sopt | Vinfast VF36 | 8 | 2022 |

| 26 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 3&4) | 39 | 2022 |

| 27 | Dabaqa Dabaqa WF | Alxanka Sopt iyo alxanka Saadaasha | Ford P703 PHEV | 29 | 2022 |

| 28 | Dabaqa WF iyo Grippers | Welding Sopt | Dabaqa Dabaqa ee Porsche E4 (21050) | 16 | 2022 |

| 29 | Tunnel Dabaqa WF | Calaamadaynta laser | Tunnel Dabaqa VW (21008) | 2 | 2022 |

| 30 | Kursiga ASSY WF iyo Qalabka | Alxanka Arc | BYD Kursiga ASSY | 40 | 2022 |

| 31 | Dabaqa Dabaqa WF | Barta iyo alxanka Arc | Dib-u-habaynta Ford | 24 | 2022 |

| 32 | CCB WF | Alxanka Arc | VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | CCB WF | Alxanka Arc | VW MQB37 (22022) | 16 | 2022 |

| 34 | A&B-Tiirka WF | Alxanka Spot | Gestamp GS2203 | 8 | 2022 |

| 35 | Saldhigga Unugga Robot | NA | VW Cyclone | 4 | 2022 |

Xarunta wax soo saarka ee alxanka

Waxaan dhisi karnaa dhammaan noocyada kala duwan ee qalabka alxanka oo ay ku jiraan cabbir weyn maadaama aan haysanno Mashiinnada CNC ee waaweyn.Qalab kala duwan oo makaanik ah sida shiididda, shiididda, mashiinnada goynta siliga iyo mashiinnada qodista, waxaan si wax ku ool ah oo sax ah u xakameyn karnaa habka socodsiinta.

25 qaybood oo CNC ah oo leh 2 shift oo soconaya

1 Qalabka 3-Axis CNC 3000*2000*1500

1 Qalabka 3-Axis CNC 3000*2300*900

1 Qalabka 3-Axis CNC 4000*2400*900

1 Qalabka 3-Axis CNC 4000*2400*1000

1 Qalabka 3-Axis CNC 6000*3000*1200

4 Qalabka 3-Axis CNC 800*500*530

9 Qalabka 3-Axis CNC 900*600*600

5 Qalabka 3-Axis CNC 1100*800*500

1 Qalabka 3-Axis CNC 1300*700*650

1 Qalabka 3-Axis CNC 2500*1100*800

5 Axis CNC -Mashiinka

4 Axis CNC -Mashiinka

Xarunta Golaha Qalabka Alxanka

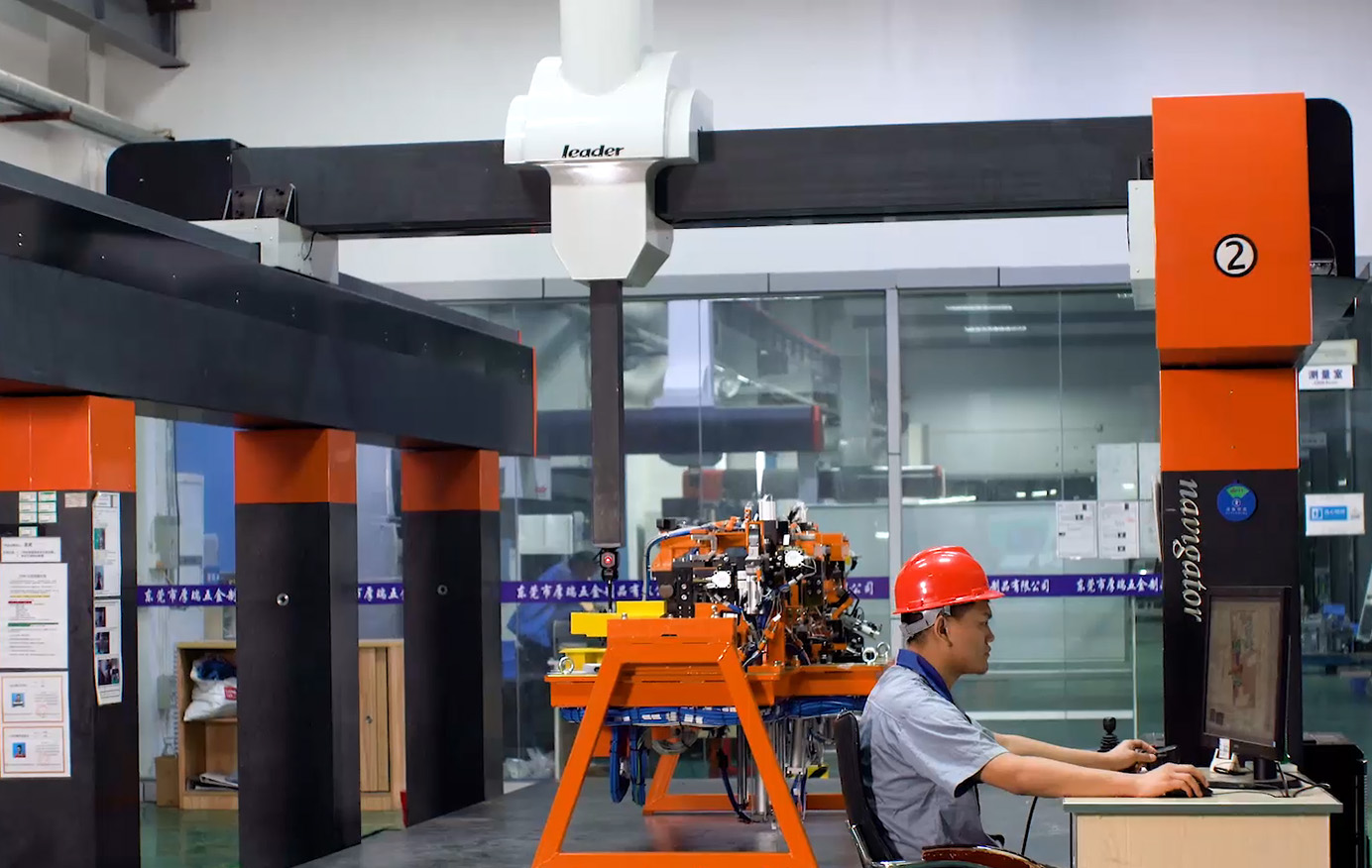

Xarunta Cabbirka ee CMM ee Qalabka alxanka

Oshaqaalahaaga wanaagsan ee tababbaran ayaa daryeeli doona wakhti kasta barnaamij kasta oo aan hayno.Waxaan sameyn karnaa wax kasta oo looga baahan yahay macaamilka, si aan u helno qanacsanaanta ugu weyn ee CMM sidoo kale.

3 qaybood oo ah CMM, 2 Shifts/Maalintii (10 saacadood saacadiiba Isniin-Sabti)

CMM, 3000*1500*1000 , Hogaamiye CMM, 1200*600*600

CMM, 500*500*400, Hexagon 2D Projector, Tijaabada Adag

.png)

.png)