Hemming die and hemming system ee warshadaha baabuurta

Horumarinta Shirkadda

- 2011, TTM waxaa lagu aasaasay ShenZhen.

- 2012, U guurista DongGuan;Dhisida xiriirka iskaashiga ee Magna International Inc.

- In 2013 Soo bandhigida qalab aad u horumarsan.

- 2016, waxay soo bandhigtay qalab CMM oo ballaaran iyo qalabka 5 dhidibka CNC;La kaashaday OEM Ford Completed Porsche, Lamborghini iyo Tesla CF mashaariicda.

- 2017, U guurista goobta dhirta hadda jirta;CNC ayaa laga kordhiyey 8 ilaa 17 qaybood.Top Talent Automotive Fixtures & Jigs Co.Ltd ayaa la aasaasay

- 2018, La kaashaday LEVDEO automotive oo waxay dhamaystirtay khadka wax soo saarka otomaatiga.4-xawaaraha sare ee CNC ayaa la soo bandhigay, wadarta Qty ee CNC waxay gaartay 21.

- 2019, Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd ayaa la aasaasay.(Hal joogsi joogsi ah) Waxay la kaashadeen Tesla Shanghai iyo Sodecia Germany.Waxa loo dhisay shaybaadhka R&D cusub ee otomaatiga ah.

- 2020, la kaashaday OEM ISUZU ee SA; Waxay dhamaystirtay Adeegga Hal-Stop ee RG06.

- 2021, horay loogu sii socdo aaminaadda tayada si loo abuuro ganacsi heer caalami ah.

- 2022, xafiiska kooxda TTM waxaa laga aasaasay Dongguan City, New CNC 4 axis * 5 sets, New Press * 630 tan, Hexagon Absolute Arm.

- 2023, TTM waxay dhisaysaa warshad cusub oo lagu hubinayo qalabka & ganacsiga qalabka alxanka;ku darida hal 2000T saxaafad.

Hubinta Qalabaynta & Warshada Qalabaynta Alxanka (Guud ahaan bedka: 9000m²)

Qalabka Shaabadaynta & Dhimashada iyo Wershada Qaybaha Mashiinnada (Guud ahaan bedka: 16000m²)

Sharaxaada Alaabta

| Magaca Alaabta | Hemming wuu dhintay |

| Codsiga | Daboolka baabuurta, albaabada, dabada iwm. |

| Nooca | Hemming die system |

| Astaanta Qaybta Pneumatic | SMC, FESTO, TUENKERS, CKD, Gacan-qabsiga |

| Calaamadda Qaybta Korantada | OMRON, Mitsubishi, Siemens, Balluff |

| Qalab | 45# Birta, Copper, Stainless Steel |

| Habka Xakamaynta | Xakamaynta Hawada (Valve Control Pneumatic) |

| Jidka isku dhufashada | Pneumatic, Buugga |

| Habka Isgaarsiinta | EtherCAT, PROFINET, CC-LINK |

| Sanduuqa Gudbinta Isgaadhsiinta | Habka santuuqa korontada, Nooca godka degdega ah, nooca jasiiradda Solenoid valve |

| Jidka dhuumaha | Tuubbada lakabka ah, tuubada ololka celisa, Tube Copper/Stael tube |

| Daaweynta Dusha sare | Rinjiyeynta, Rinjiyeynta+Black Oxidization, Zinc-Dahaaran, Rinjiyeynta budada |

| Waqtiga Hogaaminta | 2-4 toddobaad ee naqshadeynta iyo dib u eegista naqshadeynta; |

| 10-12 toddobaad ee wax soo saarka ka dib ansixinta naqshadeynta | |

| 7-10 Maalmaha shaqada ee maraakiibta hawada; | |

| 4-5 toddobaad ee cabista badda | |

| Geeri Nolosha | Waxay ku xiran tahay awoodda wax soo saarka macmiilka |

| Caymiska Tayada | Kormeerka CMM |

| Tijaabi muunado | |

| Iibsashada goobta | |

| Shirka Shabakadda Fiidiyowga ah ee khadka tooska ah iibso | |

| Xallinta Dhibaatooyinka Iibka-Off | |

| Xidhmada | Sanduuqyada alwaaxyada ee shaybaarada, sanduuqyada alwaaxyada ama sagxadaha qalabka lagu rakibo; |

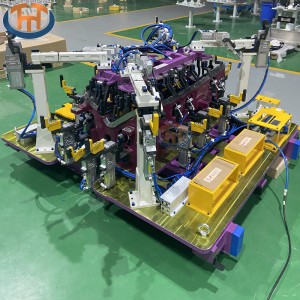

Waa maxay dhimista baabuurka?

Dhimashada gawaarida gawaarida waa qalab gaar ah oo loo isticmaalo habka wax soo saarka si loo qaabeeyo loona sugo cidhifyada qaybaha birta ah ee samaysa jidhka baabuurka.Hemming waa farsamo caadi ahaan looga shaqeeyo warshadaha baabuurta si ay ugu biiraan laba xabbo oo biraha xaashida ah iyada oo la iskula laabanayo cidhifka xaashida kan kale, abuurista tol nadiif ah oo inta badan la xoojiyay.

Ujeedada aasaasiga ah ee dhimista hemming baabuurka waa in la helo laalaab sax ah oo joogto ah biraha xaashida ah, hubinta in cidhifyada ay si ammaan ah isugu xidhan yihiin.Habkani waxa uu muhiim u yahay samaynta qaybaha kala duwan ee gaadhiga, oo ay ku jiraan albaabada, koofiyadaha, xayndaabyada, iyo qaybaha kale ee jidhka.Tayada hemming waxay si toos ah u saamaysaa sharafta qaabdhismeedka, muuqaalka, iyo cimri dhererka badeecada ugu dambeysa ee baabuurta.

Waa kuwan qaar ka mid ah dhinacyada muhiimka ah iyo shaqooyinka dhimista hemming automotive:

Qaabaynta Cidhifyada: Dhimashada waxaa loogu talagalay in lagu qaabeeyo oo laalaabo cidhifyada biraha xaashida ah si ay u abuurto muuqaal aan lahayn oo dhammaystiran.Tani waxay si gaar ah muhiim ugu tahay warshadaha baabuurta, halkaas oo bilicda iyo aerodynamics ay yihiin arrimo muhiim ah.

Xoojinta: Hemming kaliya ma bixiso muuqaal nadiif ah, laakiin sidoo kale waxay xoojinaysaa cidhifyada isku xiran, kor u qaadida xoogga iyo qallafsanaanta qaybaha la isku daray.Tani waxay muhiim u tahay ilaalinta sharafta qaab dhismeedka baabuurka.

Kala duwanaansho: Dhimashada hemming ee baabuurta waxaa loogu talagalay inay dejiso dhumucyada birta xaashida ee kala duwan iyo halabuurka, taasoo bixisa kala duwanaansho habka wax soo saarka.La qabsigani waxa uu hubinayaa in qalabka loo isticmaali karo noocyada kala duwan ee noocyada baabuurta iyo nashqadaha.

Hufnaanta: Isticmaalka hemming dhimashadu waxay habaynaysaa habka wax-soo-saarka iyadoo si otomaatig ah isu laalaabisa oo ku biirta cidhifyada birta ah.Tani waxay keenaysaa waxtarka korodhka ee wax-soo-saarka, hoos u dhaca shaqada gacanta, iyo guud ahaan wax-soo-saarka oo wanaajiyay.

Joogteynta: Gaaritaanka natiijooyin joogto ah oo tayo sare leh waa faa'iidada ugu muhiimsan ee isticmaalka hemming dies.Automation-ku wuxuu xaqiijiyaa in qayb kasta si sax ah loo soo saaray, taasoo yaraynaysa suurtagalnimada cilladaha iyo kala duwanaanshaha badeecada ugu dambeysa.

Hal-abuurnimo: Horumarka tignoolajiyada hemming die inta badan waxa lagu daraa astaamo ay ka mid yihiin nidaamyada xakamaynta la qabsiga, sirdoonka macmal ah, iyo nashqadaha caadiga ah.Hal-abuurkan ayaa gacan ka geysta kontoroolka la wanaajiyey ee geeddi-socodka hemming waxayna u oggolaanayaan in si fudud loogu dhex-geliyo habaynta wax-soo-saarka casriga ah.

Horumarinta hemming horumarsan ayaa dhintaa, sida qiyaasta PrecisionHem 2024 ee lagu sheegay jawaabtii hore, waxay muujinaysaa dadaalka socda ee warshadaha si kor loogu qaado waxtarka, joogtaynta, iyo tayada guud ee hababka wax soo saarka baabuurta.Dhimashada Hemming waxay door muhiim ah ka ciyaartaa gaaritaanka heerarka la rabo ee baabuurta casriga ah, iyadoo buuxinaysa shuruudaha shaqada iyo bilicda labadaba.

Xalka (Adeegyada Furaha Furaha)

Nidaamka Golaha Cad:

1, Hemming dhiman

2, Khadka Alxanka Jidhka Baabuurka oo Dhammaystiran

3, Keli TaagUnug alxanka

4,Qalabka alxanka iyo Jigsiyada:

CCB ASSYQalabka alxanka, Qalabka alxanka ee Pan ASSY, Qalabka alxanka ee Wheelhouse ASSY, AB Ring ASSY AB Qalabka alxanka, Kursiga ASSY Qalabka alxanka, Kursiga hore ee xubinta alxanka, Qalabka alxanka ASSY dhamaadka hore, Qalabka Dash ASSY Qalabka alxanka, Cowl ASSY Welding Welding Fixture saaraha, shirkadda naqshadeynta iyo warshadda.

Nidaamka Maareynta ISO ee Hemming Die

Kooxdayada Hemming Die

Faa'iidooyinkayaga

1.Khibrad qani ah oo ku saabsan wax soo saarka tooska ah iyo maareynta ganacsiga.

2.One Stop Service ee qalabka shaambaynta, hubinta qalabka, alxanka iyo unugyada si loo gaaro wakhtiga iyo badbaadinta kharashka, ku habboonaanta isgaarsiinta, si loo kordhiyo faa'iidada macaamiisha.

3.Kooxda injineernimada xirfada leh si ay u dhamaystiraan GD & T inta u dhaxaysa hal qayb iyo qaybta isku dhafka.

4.Turnkey Xalka Adeegga Shaabadaynta Qalabka, Hubinta Qalabka, Qalabka alxanka iyo Unugyada hal koox.

5.Awood xoog leh oo leh taageero farsamo oo caalami ah iyo iskaashi iskaashi.

6.Big Capacity: Hubinta Fixture, 1500 sets / year; Qalabka alxanka iyo unugyada, 400-600 sets / year;Qalabka Shaabadaynta, 200-300 sets/sanadkii.

Waxaan leenahay in ka badan 352 shaqaale ah, 80% ka mid ah waa injineero sare oo farsamo.Qaybinta qalabaynta: 130 shaqaale, Qaybta qalabka alxanka: 60 shaqaale, hubinta qaybta qalabka: 162 shaqaale, Waxaan leenahay iibka xirfadlayaasha ah & kooxda maareynta mashruuca, adeega muddada dheer ee mashaariicda dibadda, laga bilaabo RFQ ilaa wax soo saarka, shixnadda, iibka ka dib, kooxdayada waxay ku maareyn kartaa dhammaan dhibaatooyinka macaamiisheena Shiinaha, Ingiriisiga iyo Luuqadda Jarmalka.

Waayo-aragnimada Mashaariicda Waaweyn ee Unugyada alxanka iyo Qalabka alxanka

| Mashruuca Qalabaynta Alxanka Weyn (2019-2021) | |||||

| Shayga | Sharaxaada | Nooca | Magaca Mashruuca | Qty(Guud) | Sannadka |

| 1 | CCB WF | Alxanka Arc | VW MEB31 | 60 | 2019-2021 |

| 2 | CCB WF | Alxanka Arc | VW MEB41 | 10 | 2020 |

| 3 | CCB WF | Alxanka Arc | VW 316 | 4 | 2020 |

| 4 | CCB WF | Alxanka Arc | Ford T6 | 8 | 2021 |

| 5 | CCB WF | Alxanka Arc | ISUZU RG06 | 3 | 2020 |

| 6 | CCB WF | Alxanka Arc | Bcar, BSUV | 6 | 2020 |

| 7 | CCB WF | Alxanka Arc | Bcar,BCAR | 7 | 2020 |

| 8 | Dabaqa Dabaqa WF | Welding Sopt | SK326/0RU_K Karooq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Alxanka Arc | WL/WS | 4 | 2019 |

| 10 | Xubin-goysyada garabka WF | Alxanka Arc | WL/WS | 12 | 2019-2021 |

| 11 | Barafka hore ee WF | Alxanka Arc | VW281 | 14 | 2019 |

| 12 | Tusmada ugu hooseysa ee WF | Alxanka Arc | ISSU RG06 | 18 | 2019 |

| 13 | SL ASY iyo MBR iyo EXT ASY | Barta iyo alxanka Arc | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF iyo Unug Qaldan | Alxanka Arc | ISSU RG06 | 6 | 2020 |

| 15 | Kursiga hore ee Laanqayraha WF | Welding Sopt | Volkswagen AG MEB316 (20001) | 4 | 2020 |

| 16 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 1) | 18 | 2020 |

| 17 | Guriga Wheel WF iyo Grippers | Alxanka Arc | Ford BX755 (19018) | 6 | 2020 |

| 18 | AB Ring WF iyo Grippers | Alxanka Arc | Ford BX755 (19018) | 14 | 2020 |

| 19 | Dash Panel WF iyo Grippers | Welding Sopt | Koonfur Afrika Ford T6 (17028-1) | 10 | 2020 |

| 20 | Cowl WF iyo Grippers | Alxanka Spot | Koonfur Afrika Ford T6 (17028-3) | 6 | 2020 |

| 21 | Dhamaadka hore ee WF iyo Grippers | Barta iyo alxanka Arc | Koonfur Afrika Ford T6 (17025) | 10 | 2020 |

| 22 | Rocker WF iyo Grippers | Alxanka Spot | Koonfur Afrika Ford T6 (19029) | 8 | 2020 |

| 23 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 2) | 63 | 2021 |

| 24 | Gadaasha dambe iyo Chassis WF | Alxanka Arc | Ford P703&J73 | 36 | 2020-2021 |

| Mashruuca Qalabaynta Alxanka Weyn (2022) | |||||

| Shayga | Sharaxaada | Nooca | Magaca Mashruuca | Qty(Guud) | Sannadka |

| 25 | Xoojinta Kanaalka Dhexe WF | Welding Sopt | Vinfast VF36 | 8 | 2022 |

| 26 | Dabaqa WF iyo Grippers | Welding Sopt | AUDI/PORSCHE PPE 41(19017 Wajiga 3&4) | 39 | 2022 |

| 27 | Dabaqa Dabaqa WF | Alxanka Sopt iyo alxanka Saadaasha | Ford P703 PHEV | 29 | 2022 |

| 28 | Dabaqa WF iyo Grippers | Welding Sopt | Dabaqa Dabaqa ee Porsche E4 (21050) | 16 | 2022 |

| 29 | Tunnel Dabaqa WF | Calaamadaynta laser | Tunnel Dabaqa VW (21008) | 2 | 2022 |

| 30 | Kursiga ASSY WF iyo Qalabka | Alxanka Arc | BYD Kursiga ASSY | 40 | 2022 |

| 31 | Dabaqa Dabaqa WF | Barta iyo alxanka Arc | Dib-u-habaynta Ford | 24 | 2022 |

| 32 | CCB WF | Alxanka Arc | VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | CCB WF | Alxanka Arc | VW MQB37 (22022) | 16 | 2022 |

| 34 | A&B-Tiirka WF | Alxanka Spot | Gestamp GS2203 | 8 | 2022 |

| 35 | Saldhigga Unugga Robot | NA | VW Cyclone | 4 | 2022 |

Xarunta wax soo saarka ee Hemming Dies

Waxaan dhisi karnaa dhammaan noocyada kala duwan ee qalabka alxanka oo ay ku jiraan cabbir weyn maadaama aan haysanno Mashiinnada CNC ee waaweyn.Qalab kala duwan oo makaanik ah sida shiididda, shiididda, mashiinnada goynta siliga iyo mashiinnada qodista, waxaan si wax ku ool ah oo sax ah u xakameyn karnaa habka socodsiinta.

25 qaybood oo CNC ah oo leh 2 shift oo soconaya

1 Qalabka 3-Axis CNC 3000*2000*1500

1 Qalabka 3-Axis CNC 3000*2300*900

1 Qalabka 3-Axis CNC 4000*2400*900

1 Qalabka 3-Axis CNC 4000*2400*1000

1 Qalabka 3-Axis CNC 6000*3000*1200

4 Qalabka 3-Axis CNC 800*500*530

9 Qalabka 3-Axis CNC 900*600*600

5 Qalabka 3-Axis CNC 1100*800*500

1 Qalabka 3-Axis CNC 1300*700*650

1 Qalabka 3-Axis CNC 2500*1100*800

5 Axis CNC -Mashiinka

4 Axis CNC -Mashiinka

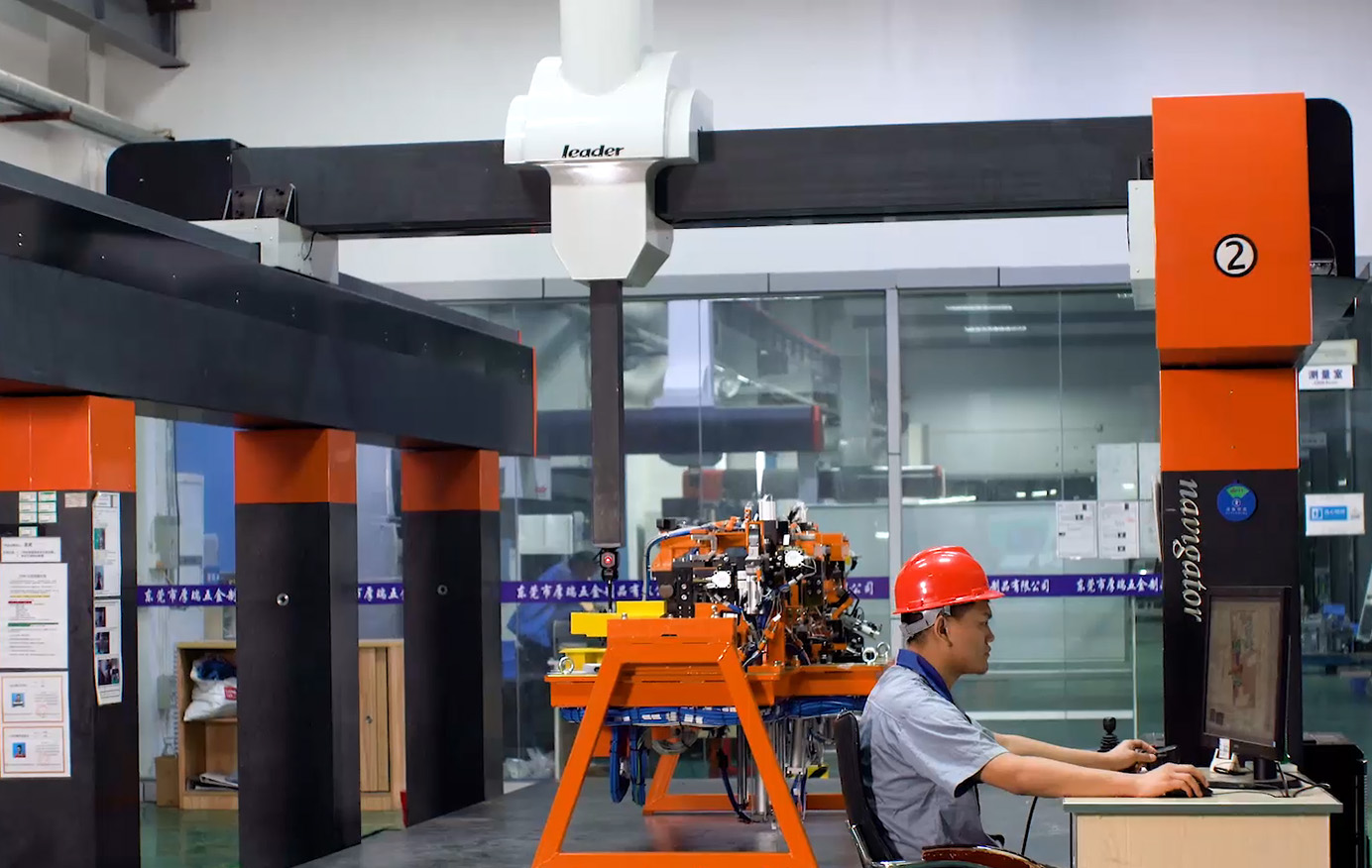

Xarunta Golaha Hemming Die

Xarunta Cabbirka ee CMM ee Hemming Dies

Oshaqaalahaaga wanaagsan ee tababbaran ayaa daryeeli doona wakhti kasta barnaamij kasta oo aan hayno.Waxaan sameyn karnaa wax kasta oo looga baahan yahay macaamilka, si aan u helno qanacsanaanta ugu weyn ee CMM sidoo kale.

3 qaybood oo ah CMM, 2 Shifts/Maalintii (10 saacadood saacadiiba Isniin-Sabti)

CMM, 3000*1500*1000 , Hogaamiye CMM, 1200*600*600

CMM, 500*500*400, Hexagon 2D Projector, Tijaabada Adag

.png)

.png)